Tibetan Engraving and Printing Techniques

Tibetan Engraving and Printing Techniques

Tibetan engraving and printing skills of Dege Printing Institute, local traditional handicraft skills of Dege County, Sichuan Province, and one of the national intangible cultural heritages.

The Tibetan engraving and printing techniques of Dege Printing School include papermaking, plate making, printing and other procedures. Paper making uses the root of Stellera chamaejasme as raw material. The production techniques belong to the watering system and are unique.

On May 20, 2006, the Tibetan woodblock printing skills of Dege Printing Institute were approved by the State Council and listed in the first batch of national intangible cultural heritage list, project number_-80. In 2009, the engraving skills of Dege School of Printing successfully entered the United Nations "representative works of the list of intangible cultural heritage of mankind".

historical origin

The engraving history of Dege Printing School can be divided into four stages:

(1) germination stage. The history of the sculptures collected by the Yinjing Academy can be traced back to at least 42 years (1703) of Kangxi in the Qing Dynasty. Before the founding of the School of Printing, there were about 1500 engravings funded by Dege Tusi, and more than 30,000 engravings from the family collection and the devotion of the poor people.

(2) The initial stage. During the reign of Twelfth Tusi Dengbazeren (1729-1739), he planned to create a printing academy and carved engravings at the same time. He completed the engraving of Ganzhul and some Danzhul engravings and other classics. The engraving volume has reached nearly 100,000 pieces.

(3) flourishing stage. From the 1840s to the end of the 18th century, the amount of engraving reached its peak. In addition to the completion of more than 64,000 engravings of Danjul, dozens of classical books have been engraved, making the number of engravings in the School of Printing more than 200,000.

(4) Maintenance phase. After the 19th century, the dominant power and economic strength of the Dege Tusi began to decline, and before that, the Tibetan edition of the Printing Academy had a considerable scale, so the engraving system gradually decreased, and some engravings were lost in the civil strife of the Dege Tusi family in the late Qing Dynasty. By 1950, over 480 books, nearly 300,000 prints and prints were carved in 277 years, and nearly 220,000 old engravings were actually collected. Since the 1980s, Dege Printing Institute has been cleaning up the documents collected in the hospital while maintaining the buildings, and doing the repairing and carving of the lost and decayed engravings. There are about 80,000 new and supplementary engravings, and nearly 307 engravings in Dege School of Printing.

Process characteristics

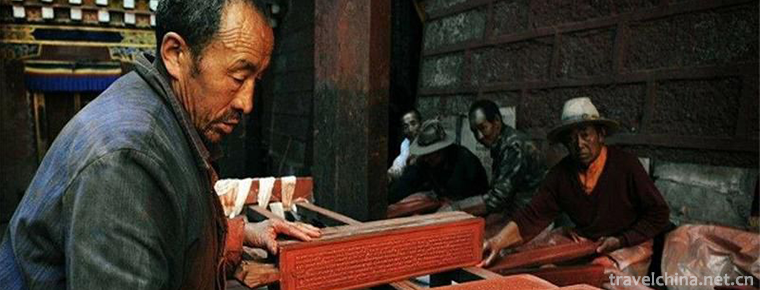

The Tibetan block printing skills of Dege Printing School include paper making, plate making and printing. Among them, the Scriptures and portraits are mostly made by hand with Stellera chamaejasme root and traditional paper-pouring method. The Tibetan paper produced by this technology has the characteristics of not being moth-eaten, strong ink absorption, light weight and good toughness. The printing process is a complete continuation of the traditional printing process. The whole printing process consists of three persons. One person is responsible for replacing the printed plate, removing the printed version, bringing in new version, brushing ink by one person, and printing by one person.

The Tibetan engraving and printing techniques of Dege School of Printing have undergone a complicated, meticulous and rigorous systematic process to produce engraving plates, which are known as "the most standard classical version of the Snow Region Tibetan School of Printing". The paper and ink used in the Tibetan engraving printing technology of Dege Printing School are made by Dege Printing School. Its paper making technology has a long history. It uses the slightly toxic root of "A Jiao Ru Jiao" as raw material, so the paper produced has the excellent characteristics of insect-free, rat-free and durable. Ink is made from the bark of "Big Dupu Tree" and a small number of branches named "Arang" which are put into the ground stove and smoked for 20 days. The ash on the inner wall is scraped off. The ink print is bright and clear, and never fades. Craftsmen are only employed after years of rigorous study and assessment. They need to understand the grammatical norms of Tibetan language and master some painting skills.

Technological process

(1) Engraving

The engraving production of Dege School of Printing can be roughly divided into raw material processing, writing, engraving and acceptance.

1. Embryo Plate Making

The raw materials for the engraving of Dege Printing School are the red birch wood which is abundant in Dege, Baiyu and Jiangda, Tibet. The red birch used in the past was reported to the chieftain after the budget of the Institute of Indian Studies was issued the next year, and the chieftain asked for it from the areas rich in red birch. After autumn leaves were yellow, the migrants went up to the mountains to cut straight and knotless red birch trees, saw the salty joints according to the required size, then cut the wood into four to five centimeters thick plates, set up on the ground and smoked and dehydrated with a light fire. After smoking and drying, they were packed back into the dunghill to make a winter. The next year, from March to April, the wood of the boards retreated and took out the slack. Dry in the dark or on the stove with smoke. Push and flatten it into embryonic version, and then carry it to the printing and warehousing Institute for acceptance. There are 5 to 6 kinds of embryos according to the need. The largest is 110 centimeters long, 70 centimeters wide and 3 centimeters thick; generally 66 to 77 centimeters long, 11 to 18 centimeters wide and 2 centimeters thick; the smallest is 33 centimeters long, 6 centimeters wide and 1.5 centimeters thick. The above is the production of classical plates, the processing and production of the prints depends on the needs of different specific.

2. Writing on Embryo

Before engraving, the Tibetan calligrapher wrote strictly in accordance with the "Tibetan Calligraphy Standard 40" and the size of the engraving. Generally, there are two writing methods: one is to write Tibetan directly on the embryo plate and proofread it before engraving; the other is to cut the thin transparent paper into samples of the same size as the embryo plate, and then write Tibetan documents on the sample paper. After proofreading, the sample paper is pasted back on the embryo plate with clear paste, and the Tibetan script will naturally permeate into the embryo plate until the sample paper dries to a certain extent. Soak it in water, remove the blank sample paper, and the handwriting is clearly displayed on the embryo.

3. Engraving

The engraving craftsmen of Dege Printing School are trained by their masters and apprentices. Only after strict examination and selection of skilled people can they engage in the task of engraving. Carving artists should not only be skilled in techniques, but also have a good foundation in Tibetan techniques and painting. Especially the craftsmen of engraving prints must understand the basic principles of composition and basic skills of painting.

4. Acceptance

In order to ensure that the engraving is deep, accurate, precise and well carved, Dege School of Printing stipulates that each person is allowed to carve only one inch of the page every day. After the plate is first carved out, a printed sheet is first printed and handed over to a specialist for alphabetical evaluation, and then proofreading and proofreading is carried out. The errors, omissions, missing words and other errors are digged and corrected. The acceptance batches of engravings are then soaked and boiled in a butter pot, and then dried, so that the butter can penetrate into the engraving plate. Then, the local plant root called "Suba" is boiled and washed and dried. After that, it can be mounted on the Tibetan plate shelf. The whole engraving process in processing, writing, sculpture, acceptance and so on, through more than 15 processes, more than 10 times of proofreading and acceptance. Therefore, the engraving of Dege School of Printing is praised as "the most standard classical version of the Tibetan School of Printing in Snow Regions" in Tibet.

(2) Dege ink-making

There are two kinds of ink used in Dege School of Printing. One is for writing and the other is for printing. The ink used for printing is mostly the bark of the big azalea tree (Tibetan is called "Zhao Xia"). When local people make ink, they first dig a stove in the place where Rhododendron trees are abundant, and build a small sealed and airtight wooden shed on the stove. Then they put the collected Rhododendron bark and a small number of "Alang" branches into the stove and smoke for 20 days to 1 month. After quenching and cooling, they open the closed wooden shed, scrape the ash attached to the wall of the wooden shed, and grind it carefully. It can be packaged for use. The smoke made from Rhododendron bark and a few "Alang" branches is soft and delicate, and the ink is bright. When used, only a proper amount of water is needed to blend, because the bark and branches of the two trees are contaminated and need not be glued. The cigarette ink used for writing official letters is usually made of local willow leaves and part of "Alang" branches. The firing method is the same as that of printing ink. When grinding, it can be properly added with cow glue, and when writing, it can be blended with appropriate amount of water. The color and handwriting are always bright, neither changing nor fading.

(3) Dege Paper Making

Dege has a long history of papermaking. According to relevant records, the first year of Turkey in Tibetan history, that is, 1078 A.D., the paper Tibetan language used in the handwritten biography of King Ling Gesar appeared in Dege, which means the paper made by Dege Gongkuang Alecun (now known as Xiege Village). The paper-making raw materials of Dege Printing School are very unique. A kind of plant root is used, which is called "A Jiao Rujiao" and translated into "Stellera chamaejasme". A Jiao Rujiao can be divided into three layers: inside, middle and outside. It can produce three kinds of paper of different quality. If the middle layer is used as paper, it is first-class paper, which is delicate in quality and white in color. It is special paper for Dege Tusi official documents. If the inner layer and the outer layer are used together, it is second-class paper, which is the main printing paper of Dege Printing School. If the inner, middle and outer layers are used together, it is third-class paper, which is of poor quality, thicker paper and thicker fibers. It is generally used for printing "loading" scriptures and Feng Ma (dragon beating) and so on. Printing and packaging paper. Since ancient times, people in Dege area have been in the habit of collecting "A Jiao Ru Jiao" regularly. After picking, they wash out the sediment first, and then stratify the roots according to their needs (if making third-class paper, there is no need for stratification process). After layering, the roots were beaten for a period of time, then the beaten pulp was beaten, dregs were removed, alkali was added, and the pulp was stirred repeatedly in a "drop bucket" similar to butter tea to make the pulp uniform. The subsequent production method was roughly the same as the traditional paper-making process in the Mainland. Dege paper made from "A Jiao Ru Jiao" is yellowish in color, coarse in texture and thicker in thickness, but the fibers are flexible, non-fragile and highly absorbent. At the same time, because "Ajiao Rujiao" itself is a Tibetan medicinal material with slight toxicity, the paper made has the characteristics of insect-free, rat-free and long-term storage for thousands of years, and is an ideal paper for preserving documents.

(4) Primitive printing skills

Dege Printing School adheres to the traditional printing skills, the whole printing process is completed by three people: one person to carry engraving, one person to brush ink, one person to print. The printing process of Dege School of Printing can be roughly divided into four parts: paper cutting, pigment processing, printing and binding. Subdivision can be divided into 20 processes: paper cutting, paper soaking, ink mixing, grinding, development of cinnabar, engraving, printing, engraving shelf, drying, plate washing, plate drying, polishing, oil cleaning, page separation, inspection, binding, polishing, packaging, edge red, warehousing, etc. The above processes are not only running water operations, but also cross each other, orderly, all completed by hand.

Inheritance and protection

Inheritance value

historical value

The Tibetan block printing skills of Dege Printing School are old and unique. For a long time, it has played a tremendous role in the continuation of Tibetan culture, even Chinese culture and world culture. Many classics and paintings of literati and Mohists have been inherited through it. At present, its engraving, papermaking, printing, binding and many other technologies basically maintain the traditional skills in history, providing a rare example of both old and fresh, real and simple engraving and printing civilization that has gradually disappeared.

Cultural value

Chinese block printing originated in the late Northern and Southern Dynasties and was later replaced by movable type printing. More than a thousand years later, printing has developed into the era of computer photo typesetting and high-speed color printing. In the Dege School of Printing in the Tibetan area of China, there are still ancient techniques of block printing. Dozens of craftsmen have produced a book with pure handicraft in dozens of working procedures. Therefore, Dege's engraving and printing technology has important cultural value. Its own characteristics will be popular in the world with Chinese calligraphy and painting art.

Process value

The production process of Dege's engraving printing technology is complex. For example, the printing of texts is divided into 15 processes: cutting, soaking paper, ink mixing and grinding cinnabar, printing, drying, plate washing, storage, pagination, proofreading, binding, etc. Among them, the fineness and requirements of each process are higher than those of other similar production. Such fine printing technology is unique in the whole Tibetan School of Classics and even in the world. These production techniques are the crystallization of the long-term wisdom of the working people of China. They contain rich scientific and technological genes and are an extremely valuable historical heritage.

economic value

Firstly, the preservation and development of Dege's engraving printing technology can solve the employment problem of a considerable number of local people; secondly, the documents and books printed by Dege's Institute of Printing are not only widely disseminated in the vast Tibetan areas of China, but also collected by many museums and research institutes in China, and are also exported to India, Nepal, Bhutan, Sikkim, Japan and some countries and regions in Southeast Asia. Some important books have been collected by famous libraries in Asia, America and Europe, so they can be exported to earn foreign exchange.

Inheritance status

Due to the high production cost of handicraft, the complex process, the unresolved production process of Tibetan ink and other problems, and the replacement of movable-type printing technology by more advanced computer photo typesetting, the inheritance of Tibetan engraving printing technology in Dege Printing Institute has encountered difficulties. It is urgent to take measures to protect and realize the inheritance, so as to make a dazzling cultural heritage of the Chinese nation long. Stay in the world.

Inheriting characters

Peng Tsuozeren, male, was born in October 1955. In June 2007, Peng Tsuozeren was selected as the representative successor of the first batch of national intangible cultural heritage projects and declared in Dege County, Sichuan Province. Project Name: Tibetan Engraving and Printing Techniques of Dege Printing Institute.

protective measures

On November 20, 1996, with the approval of the State Council of China, the Dege School of Printing was listed as one of the key protected cultural relics units in China.

In 2000, an 80-year-old man was invited to teach young people how to make Tibetan paper, which initially saved this traditional skill.

Peng Kuo Zeren, the inheritor of Tibetan engraving printing skills in Dege Printing School, received about 50 apprentices.

social influence

Important exhibition

From February 9 to February 23, 2009, the exhibition of traditional techniques of intangible cultural heritage of China was held in Beijing, in which the Tibetan block printing techniques of Dege Printing Institute were displayed.

From November 10 to 15, 2015, the 2nd China intangible cultural heritage traditional art exhibition was held in Shexian County, Huangshan City. The Tibetan block printing skills of Dege Printing Institute were displayed in the exhibition.

Honorary commendation

The work Prajna Eight Thousand Songs is the only solitary edition left in the world. It was approved to be included in the Chinese Archives and Documents Heritage List in March 2002 and is known as one of the "three treasures of Kangba".

The works Ganzhul and Danzhul were recognized as the only standard editions by the Chinese Tibetology Research Center and the Sichuan Dazang Classic.

-

Yandang Mountain Scenic Spot

Yandang Mountain, the first batch of national key scenic spots, has the titles of "Sanitary Mountain, Safe Mountain, Civilized Mountain", National Civilized Scenic Spot, National AAAAA Touri.

Views: 190 Time 2018-12-07 -

Wushan small Three Gorges

The Little Three Gorges, or the Little Three Gorges Tourist Scenic Spot, was named "Forty Best Tourist Resorts in China" in 1991, "National AAAA Tourist Scenic Spot" in November 20.

Views: 150 Time 2018-12-12 -

XiShuangBanNa Tropical Botanical GardenChines

Xishuangbanna Tropical Botanical Garden of the Chinese Academy of Sciences, National AAAAA Tourist Scenic Area, is located in Huludao, Mengla Town, Mengla County.

Views: 93 Time 2018-12-12 -

Qibugou Scenic Area

Qibugou Scenic Area is located in Wu'an Huoshui Township, Handan City, Hebei Province. Wu'an National Geological Park and the hinterland of the National Forest Park, Hebei Province.

Views: 172 Time 2018-12-17 -

Water Curtain Gorge Scenic Area

Shuixian Gorge Scenic Area is located in the southern mountain area of Jinan, Liubu, the first town of ecotourism in Shandong Province. Covering an area of more than 6000 mu, Jinan's No. 1 Peak Ladder.

Views: 170 Time 2019-02-13 -

Gudou Hotspring Resort

Xinhui Gudou Hot Spring Resort is located in Gudou Scenic Area, 55 kilometers away from the Capital City, 5 kilometers away from the entrance and exit of Xinhui Cliff South Section of the West Coastal.

Views: 208 Time 2019-02-25 -

Babao black rice porridge

Babao black rice porridge is a traditional snack and a food for Laba Festival. Purple and black, soft and waxy, sweet and fragrant. Developed from Babao glutinous rice porridge, it has the function of.

Views: 172 Time 2019-03-25 -

tea and pastries making skills

Tea making skills, Yangzhou City, Jiangsu Province, local traditional handicraft, one of the national intangible cultural heritage..

Views: 155 Time 2019-04-15 -

Shangdang Laozi

Shangdang Laozi is one of Shanxi local operas. It is a kind of opera popular in southeastern Shanxi. Shangdang Laozi is a tributary of Wu'an Laozi in Hebei Province. During the Daoguang period of the .

Views: 379 Time 2019-06-13 -

China Foreign Affairs University

China Foreign Affairs University is a small scale, high level and distinctive foreign ministry's sole institution directly under the guidance of serving the cause of China's diplomacy and cultivating .

Views: 170 Time 2019-11-29 -

Chinese Qiang Museum

Qiang museum is a local ethnic Museum, located in the south of Qiangxing street in Maoxian county. It was officially opened in 1988 when the Qiang traditional festival "Qiang calendar year". It is the only Qiang Museum in China..

Views: 101 Time 2020-11-06 -

Time and reason of Ding Zhen popularity

Ding zhenhuo, a 20-year-old Tibetan Boy from Ganzi, Sichuan Province, was caught up in a short video of less than 10 seconds. The uploader of the video and the photographer "BOGO" who shot Ding Zhen also attracted netizens' attention. Talking about his first impression of Ding Zhen.

Views: 241 Time 2020-12-06