Printing and Dyeing Techniques of Blue Printed Cloth

Printing and Dyeing Techniques of Blue Printed Cloth

The printing and dyeing technology of blue printed cloth is a kind of anti-dyeing and printing method of indigo printed cloth. The dye is extracted from Polygonum multiflorum. The paste made of soybean flour and lime for anti-dyeing is commonly known as "grey medicine". The paste is leaked to the grey cloth through the type plate and forms patterns. After the cloth is soaked and dried, the part of the "grey medicine" removed is white pattern, and the other is the color dyed. Nowadays, blue printed cloth can be divided into two forms: blue ground white flower and white ground blue flower. Blue and white patterned cloth is printed with only one plate, and the patches of the patterned pattern are not connected with each other.

In 2006, the "Nantong Blue Printed Cloth Printing and Dyeing Techniques" declared by the Nantong Blue Printed Cloth Museum of China was declared as a national intangible cultural heritage by the State Council. Wu Yuanxin was selected as the representative inheritor of the printing and dyeing technology of the national intangible cultural heritage blue print cloth. On June 7, 2008, the printing and dyeing techniques of blue printed cloth were approved by the State Council and listed in the second batch of national intangible cultural heritage lists. On May 24, 2018, it was selected as the first national catalogue of revitalization of traditional crafts.

History

According to historical records, the clothes worn by the women's corpses unearthed in Mawangdui, Changsha, were covered with high-quality blue calico printing and dyeing. It can be seen that, in the Western Han Dynasty, printing and dyeing blue cloth has been popular among the people. In the book Tiangong Kaiwu of the Ming Dynasty, Yingxing of Song Dynasty recorded that indigo could be extracted from tea blue (i.e. Isatis indigotica), Polygonum blue, Malan blue, Wu blue and amaranth, and described the method of making blue at that time. There are two kinds of blue calico: one is pure blue calico printing and dyeing, the other is coloured blue calico printing and dyeing.

Characteristic

Phoenix blue cloth printing and dyeing from production to finished products, printing and dyeing need to go through dozens of processes, especially blue cloth printing and dyeing patterns, rich and colorful content. Blue cloth printing and dyeing on the printing of various patterns, mainly by the dyer's early production of patterns, and then printing and dyeing.

Flower carving

When making, the Dyer must first design these patterns, and then carve these patterns on the pre-made model plate. The most complicated and arduous process of the Dyer is carving these patterns. Generally speaking, it takes 5-7 days to make a 2-meter x 1.5-meter model plate and more than 3 days to make a 1-meter x 2-meter model plate. It takes much more time than a painter to draw a Chinese painting. The engraving is divided into two patterns: white flower with blue background and blue flower with white background. The engraving methods include blue-background and white-flower Yin engraving method, white-background and blue-white-flower Yang engraving method and blue-white-background combination engraving method. With smooth pebbles, the reverse side of the carved pattern is polished and smoothed, and then the tung oil is brushed repeatedly.

Blue and white flowers, only a pattern, the pattern is not connected. Blue flowers on the white background are usually overprinted with two plates. The first plate is called the "front page". After a little drying, the second plate is called the "cover plate". That is to say, the connection part of the first plate is covered up to make the pattern connect naturally. It is difficult to carve blue flowers with white background. They are usually made by folk artists. The traditional process of intersecting blue and white bottoms has a complicated manufacturing process.

Pattern type

Blue cloth printing and dyeing is a fine product in printing and dyeing. The various patterns displayed on the cloth are taken from the daily production, living customs, expectations and ideal customs of the people. Such as "the Phoenix wears peony", "the beautiful moon", "the mandarin duck plays with water", "the Heron tramples on the lotus", "magpies make plums" and other patterns. These patterns not only represent the people's likes and dislikes, but also represent the wishes and blessings of the people. The folklore culture is very profound.

Printing and dyeing process

Blue cloth printing and dyeing process is complex, many links, mainly divided into four parts, the first part is plate-making, the second part is printing, the third part is dipping, the fourth part is desizing and rinsing.

First, plate-making is divided into mounting plate, drawing, typesetting, polishing oil, after finishing oil placed in the shade of air-drying, so that a finished version was born.

2. The printing material is mixed with soybean powder and lime, the ratio is 3:7, soybean powder 3:7, lime 7. The materials must be prepared the night before printing.

Printing, printing material strength must be appropriate, otherwise affecting the fineness of the color, printed samples must be put in more than 20 minutes dry, then the soaking process, must be completely soaked with water samples.

3. The dyestuff for dipping is a kind of natural plant dyestuff called indigo. The longer it is put in the dyeing barrel, the better. The number of times of dyeing cloth is about six to eight times. Each dyeing must be placed on the dyeing barrel for oxidation for a period of time. The whole dyeing process takes 3-4 hours. After the last dyeing, it is placed in the air to oxidize and fix the color.

Fourth, desizing and rinsing part, after rinsing is completed, then drying and flattening, a finished product is completed.

Culture

Phoenix blue calico printing and dyeing, a traditional folk handicraft, is not only a folk handicraft, but also a folk culture. From the introduction and records of various historical materials, it is not only used by the majority of the Han people, but also widely used by other minority people, especially in remote minority areas, the inheritance and application of printing and dyeing indigo technology is very common. As a kind of culture, its connotation is very profound, and this special cultural quality is the common ownership of the Chinese nation.

inherit

Blue calico printing and dyeing can go to today, after years of ups and downs, the progress of the times, the continuous innovation of technology, mechanism printing and dyeing technology replaced manual technology, machine printing and dyeing products gradually replaced manual products. The folk handicraft printing and dyeing of Liu's ancestral blue-print cloth in Tuojiang Town of Phoenix is an exclusive folk handicraft technology that continues to this day. The folk handicraft technology of printing and dyeing is shown in its complex technology, exquisite production, delicate and careful operation, fine texture, simple and elegant, and has high artistic value and cultural research value.

Printing and Dyeing Techniques of Blue Printed Cloth

-

dalian forest zoo

Dalian Forest Zoo is located in Baiyun Mountain Scenic Area, Dalian, covering an area of 7.2 square kilometers. The zoo is divided into two parts: the first phase of captivity and the second phase of

Views: 176 Time 2019-01-06 -

Longtan Park

Longtan Park is located opposite Longtan Beili District, Dongcheng District, Beijing (Chongwen District), and is currently a national 4A-level tourist park. Longtan Park

Views: 157 Time 2019-02-06 -

Pingyao Ancient City Scenic Spot

Pingyao Ancient City is located in Pingyao County, central Shanxi Province. It was founded in Xuanwang Period of Western Zhou Dynasty (827-782 BC).

Views: 173 Time 2019-02-07 -

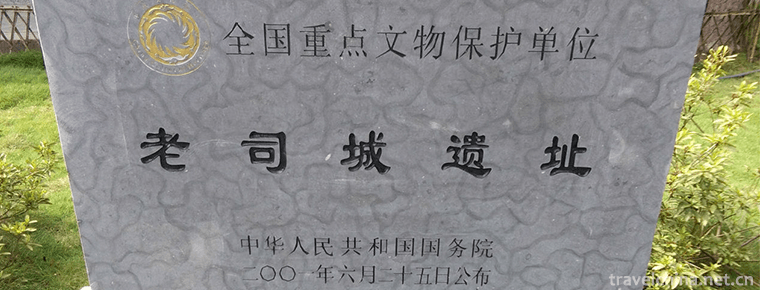

Yongshun Tusi City Site

Laosicheng Site in Yongshun, Hunan Province, is located in Laosicheng Village, Lingxi Town, more than 20 kilometers east of Yongshun County, Tujia and Miao Autonomous Prefecture

Views: 235 Time 2019-03-05 -

Hebei Drum Music

Hebei drum and percussion music is a local traditional music mainly composed of percussion instruments and percussion instruments. It has been an important type of music

Views: 161 Time 2019-05-02 -

Tujia Waving Dance

Hand-waving dance is an ancient traditional dance of Tujia nationality. It mainly spreads in the Youshui River and Wujiang River basin at the junction of Hubei, Hunan, Chongqing and Guizhou. It mainly

Views: 128 Time 2019-06-23 -

Xiangyuan Drum Book

Xiangyuan Drum Book is a traditional opera in Shanxi Province. Originated in Xiangyuan, Shanxi Province, it is popular in Shangdang area. It is also called Guer Ci and Xiangyuan Tune. According to leg

Views: 284 Time 2019-07-06 -

Xuanbi Production Skills

Xuanbi has a long history. Originated in the Qin Dynasty, it flourished in the Tang and Song Dynasties. At the end of Song Dynasty and the beginning of Yuan Dynasty, there were frequent wars, and the

Views: 160 Time 2019-07-09 -

Yao Opera

Yao Opera is popular in Yuyao, Cixi, Ningbo, Zhoushan, Shangyu and Shaoxing. It developed on the basis of folk singing and dancing "horse lantern", "dry boat" and "tea basket&

Views: 320 Time 2019-07-11 -

Recitative

Recitation is a local traditional music form in Changzhou City, Jiangsu Province, which has a high reputation at home and abroad. The art of reciting belongs to "minority culture", which is

Views: 105 Time 2019-07-13 -

Capital Normal University

Capital Normal University (Capital Normal University), World class discipline construction universities , Ministry of Education of the People's Republic of China And Beijing Municipal People's Governm

Views: 182 Time 2019-09-22 -

Cuiping Mountain Park

Cuipingshan Park, located in the northwest of Yibin City, Sichuan Province, is a famous urban forest park integrating scenic spots and forest scenery. It is mainly composed of Cuiping mountain and Zhenwu mountain.

Views: 151 Time 2020-10-16