Pottery Firing Techniques

Pottery Firing Techniques

Pottery refers to the clay as the body, processed and shaped by hand, wheel system, moulding and other methods, and baked at high temperature of 1000-1200 degrees or so. The production process of pottery can be divided into four steps in sequence: raw material processing (including mud and glaze mixing), mud body moulding, glazing and calcination. The production of pottery in China has a long history of 11700 years.

brief introduction

The key factors for firing pottery are clay, glaze and fire. Why do some pottery inexplicably crack? Why does it sometimes even peel (glaze)? This is just the result that the shrinkage coefficient (also called expansion coefficient) of mud and glaze is not the same at a certain temperature. Sometimes people will make special use of this defect. Some texture pursuits of traditional open glaze and modern ceramics are based on the principle that the shrinkage coefficients of glaze and mud are not consistent.

Development of Pottery Making Technology

executive summary

Ancient and modern crafts are much the same.

Pottery refers to the clay as the tire, after hand-kneading, rotating, moulding and other methods of processing and forming, in the 1000-1200 degrees of high temperature baked goods, varieties of grey pottery, red pottery, white pottery, painted pottery and black pottery. It has a strong flavor of life and unique artistic style. As early as the Shang Dynasty, glazed pottery and hard glazed pottery with initial ceramic properties had appeared. The contents of pottery are varied. Animals, pavilions and daily necessities are all involved. The invention of pottery is an important process of human civilization - it is the first time that human beings make use of natural things and create a brand-new thing according to their own will. According to the late Paleolithic pottery pieces found in Nihewan area, Yangyuan County, Hebei Province, the production of Chinese pottery has a long history of 11700 years.

Pottery is made of mud (clay) and dried, then fired. It is the crystallization of mud and fire. Our ancestors have known clay for a long time. As early as in the life of primitive society, their ancestors were inseparable from clay. They found that the clay soaked in water was sticky and plasticity, and became hard after drying. The use and understanding of fire has a very long history. It began to use fire in the Yuanmouren era about 250,000 to 700,000 years ago. In the long primitive life, the ancestors found that the dried mud became stronger, harder and waterproof after being burned, so pottery came into being. The invention of pottery has opened a new page for human beings to use, transform and fight against nature. It has great historical significance and is a milestone in the history of human production and development.

archaeological discovery

According to archaeological materials and research, the invention and application of pottery in China has a history of nearly ten thousand years. Among the many Neolithic sites in the Yellow River Basin and Yangtze River Basin, a large number of pottery have been unearthed. Among them, the Wannian Xianrendong site in Jiangxi Province and the Zhenpiyan site in Guilin, Guangxi, have unearthed pottery for more than 8,000 years. The selection and processing of raw materials is the first step in ancient pottery making in China. The clay with high iron content, moderate viscosity and strong plasticity should be selected as raw materials. In order to enhance the moulding performance of the clay and the heat resistance of the finished product and increase the yield of the finished product, it is necessary to add scraping materials (quartz, feldspar, sand powder, grass lime, broken pottery, etc.) into the clay. After the raw material is prepared, it must be crushed to reduce the granularity and make the mud delicate. Kneading and staleness are the last steps of raw material processing to enhance the plasticity of sludge. The second is the formation and modification of green bodies. There are two main forming methods: hand-made method and wheel-made method. The most common method of hand-made pottery is clay bar and tray method. Firstly, the mud blank is kneaded into mud strips, which are spirally wound upward from the bottom to the edge of the mouth, and then smoothed with hands and wooden rackets inside and outside, and various types of appliances are made. Small pottery can be directly kneaded by hand. Local moulding is often used for some special shapes, such as mandibles. The wheel method is to place mud on a fast-turning pottery car, with both hands rotating with the wheel, plastic pull out of the shape. After polishing and modification, it becomes the body to be burned. After the body is dried, it can be roasted in the kiln. If making painted pottery, painted pottery should be painted before baking.

Roasting in kiln is the key process of making pottery. The firing temperature is generally 1000-1200 C. At first, people may stack firewood on the flat ground and put the green body on it to ignite. This method can not reach a certain temperature because of the lack of fire concentration, resulting in poor quality of fired pottery and low yield. Later, pottery kilns were invented. According to archaeological data, there were two types of pottery kilns in the Neolithic Age, i.e. horizontal-cave kilns and vertical-cave kilns. Horizontal cave kiln is a typical kiln. It consists of a burner, a hearth, a fire channel, a kiln chamber and a grate. The kiln chamber is round, with a grate on the bottom and many holes on the grate. The flame entered by the hearth reaches the kiln chamber through the fire channel and the grate. The chamber of vertical cave kiln is above the chamber of fire. The chamber of fire is a pocket pit with small mouth and large bottom. There are many vertical channels leading to the chamber. Hengcave kilns and vertical cave kilns have been found in Yangshao and Longshan cultural sites such as Banpo in Shaanxi, Miaodigou in Shaanxi, Fanjiazhuang in Anyang and Jiangou in Handan, Hebei.

There are many kinds of Neolithic pottery, including grey pottery, red pottery, colored pottery, black pottery, white pottery, glazed pottery and so on. The reason why pottery presents different colours is that the raw materials of pottery contain colouring elements and people can change and control the nature of flame in the later stage of kiln firing. Grey pottery is in the later stage of the kiln, using reduction flame, so that most of the iron oxides in the raw materials of pottery are converted into ferrous, in this case, the fired pottery is gray or gray-black. Grey pottery is one of the most popular pottery in people's daily use. Its texture is loose and rough. Red pottery is fired in the atmosphere of oxidation flame, and its texture is hard and meticulous. Coloured pottery is the most exquisite pottery in the cultural relics of the Neolithic Age, and the painted pottery of Yangshao Culture can be regarded as its representative work. Coloured pottery pattern is painted on the body with iron, manganese and other pigments before the pottery billet is roasted in the kiln, and fired in an oxidation flame after entering the kiln. Painting is firmly combined on the surface of the utensils and is not easy to fall off. The decorations on the painted pottery include plant patterns, animal patterns and geometric patterns with various shapes. Common utensils include eating utensils, storage utensils and water absorbers. Such as bowls, bowls, basins, plates, cups, cans, bottles, etc. The fish-pattern pottery basin unearthed from Banpo Site in Xi'an is exquisitely made and has a strong interest in life. The dance-pattern pottery pots unearthed in Qinghai vividly depict the collective dance scenes of a group of five people, which can be regarded as a fine piece of painted pottery. Another kind of painted pottery is painted after firing, which is called "painted pottery after firing". The color is easy to peel off. The terracotta warriors and horses in Qinshihuang Mausoleum are painted pottery. Black pottery is roasted with oxidation flame in the early stage and fumigated with smoke at the end of the kiln (at this time, the flame is reduction flame). After a short time of penetration, it appears black. The firing temperature is about 1000 C. Some black pottery surfaces are black and shiny, and the body is as thin as the eggshell. White pottery is a kind of white pottery made of kaolin. Its fetus is delicate and hard. The firing temperature is about 1000 C. In the south of the Yangtze River and along the southeast coast of China, special printed hard pottery has been unearthed. Since then, glazed pottery, called glazed pottery, has been created and fired. There are two common types. One is that the fetus is gray, the fetus is hard, and the surface of the utensil is covered with gray transparent green glaze. The firing temperature of the glazed pottery reaches 1200 degrees Celsius. Its physical properties are close to those of porcelain. The raw material is kaolin. Its water absorption is very low. Its temperature is 1200 C. It has metallic sound. Therefore, this glazed pottery is called primitive celadon. The other is the low temperature glaze with red tire and green, yellow and brown surface. Lead is used as flux in the glaze, which is called lead glazed pottery. It appeared in the late Western Han Dynasty. Tang Sancai is low temperature glazed pottery.

Ancient humans lived mostly by mountains and rivers. They needed to find instruments to store, draw, store and cook food. Technically speaking, it has been known for a long time that the soil with water is plasticity, and the rich experience of using fire are the prerequisites for making pottery. Another condition is to "settle down". Because pottery is not easy to carry, it is heavy and easy to break. Certainly, the production of pottery has led to the gradual consolidation of settlement life.

It is speculated that the ancients painted clay to make the branched vessels fireproof and seamless. After burning, the clay part was very hard. It was found that the moulded clay could be fired without internal containers, which may be the most primitive pottery. Others believe that the ancients discovered pottery by chance because they found that the artifacts made by hand became strong after being burned, and they were not afraid of water. Remaining pottery pieces of the early Neolithic Age have been found in China about 1000 years ago. The pottery fragments found at the Nanzhuangtou site in Xushui County, Hebei Province, were identified as relics dating from 10800 to 9700. In addition, pottery fragments dating from 10,000 to 7,000 years ago were also found in Wannian County, Jiangxi Province, Zhenpiyan County, Guilin Province, and Qingtang County, Yingde County, Guangdong Province.

The early Neolithic pottery fragments have been found in China, which are rough in texture, varying in thickness, mixed with quartz grains of varying sizes, and fragile in texture. The raw materials used to make these pottery are all in-situ earthenware. According to the minerals in these pottery pieces and the firing temperature of a few pottery pieces, it can be determined that the firing temperature of these pottery pieces is about 700 degrees C. No kiln remains were found in these sites, so it can be inferred that they were heaped on flat ground. They are all small pottery, such as pots and bowls, which are made of pans or hand-made pottery. Although these pottery materials are rough, simple in shape and low in firing temperature, it is after all an attempt by human beings to use chemical changes to make utensils, which greatly improved the quality of life of primitive people.

The pottery of Yangshao culture period 5,000 years ago is mainly red pottery, followed by gray pottery and black pottery. The matriarchal clan society in the Neolithic Age at that time. From the unearthed cultural relics, the pottery industry at that time was relatively developed. Most of the pottery kiln sites excavated were near villages, indicating that they were collectively owned by tribes. The clay of fired pottery is selected to have certain plasticity. Pottery is basically hand-made, and some small devices are moulded. Slow wheel dressing began to appear in the late Yangshao period. Pottery kilns are widely used for firing pottery. In the pottery kiln, the pottery is no longer roasted directly on the flame, and the firepower is relatively uniform, which reduces the cracking and deformation of the pottery. This is a considerable progress. Fine clay painted pottery can best reflect the level of pottery production at that time. Its surface is red, its inner surface is polished, and its shape is unique. It can be seen that the pottery making technology at that time has reached a quite mature stage. In addition, there are vivid and beautiful patterns painted on these pottery, which fully reflects the imagination and creativity of the painter. All these provide us with reliable information about the life and production of the ancestors of primitive society.

Ten thousand years ago, when the original kiln was fired, the red pottery became red because of the contact between the green pottery and a large amount of air.

Seven thousand years ago, red, white and black patterns were used on the surface of pottery blanks. After being fired in kilns, the patterns adhered to the surface of pottery objects, which is called painted pottery.

Gray pottery was the main pottery in Longshan culture period. The treasure of pottery making technology was black pottery, which had thin walls like eggshells and a hard thickness of only 1-3 mm. Its surface was dark and glossy. The key technology of firing this kind of pottery is to seal the top of the kiln with mud and infiltrate water into the kiln at the same time to smoke and carburize at the later stage of firing.

In the late period of Longshan Culture in the Central Plains, a kind of printed hard pottery appeared along the South and Southeast coasts of the Yangtze River, which is called the printed pottery culture. Due to the relative increase of acid oxides in raw materials, the sintering temperature reaches 1100 degree C. By the Shang Dynasty, printed hard pottery began to be produced in large quantities. Its water absorption rate is beautiful, hard and durable, and it has become a popular pottery variety.

Production sequence

This paper introduces mud mixing, shaping, glaze mixing and calcination.

Mixing mud

The purpose of mud mixing is, on the one hand, to remove impurities, on the other hand, to mix the soils from different sources and with different forming and calcining properties into ripe soils which meet the needs of the producers and have a certain range of firing temperature and can correspond to glaze and calcining temperature. Sometimes in order to strengthen the support of mud in high temperature calcination, so that the green body does not collapse and appropriate infiltration of sand. Sometimes in order to pursue the colour and lustre of pottery firing, some colouring materials are added to become "colour tires". The chemical composition of ceramics is basically the same as that of ceramics. Because of weathering and re-weathering, the physical properties of ceramics are changed, resulting in greater viscous and plasticity of ceramics. The degree of vitrification of ceramics is different from that of brittle ceramics at high temperature.

Forming

The preparation of the blank is to knead the clay:

It is to put the mud in the center of the car surface, turn the wheel, grasp the mud in the center with the opposite force of wrist and finger, and then repeatedly pull the mud up and down with both hands, so that it can further eliminate the bubbles in the mud and make the mud more "ripe".

Glaze

Glazing methods: immersion, coating and spraying.

Glaze immersion is to immerse the whole body in a suitable dilute glaze, so that it naturally adsorbs to a certain thickness.

Glazing is done with a brush dipped in glaze powder and then applied to the body. The side edge of the brush will also have a special effect.

Spraying glaze is spraying the glaze medicine into the body with a sprayer.

calcination

Calcination is the last and most critical step.

Pottery kiln

The most critical process in making pottery is firing in kiln. In pottery kiln, the high temperature produced by wood fuel causes the chemical reaction of pottery clay, which results in the change of composition, properties and color of green body. The structure of pottery kiln determines the firing temperature of pottery to a great extent. The more reasonable the structure, the higher the firing temperature, the more solid and durable the pottery will be. The sealing condition of pottery kiln can not only affect the temperature in the kiln, but also cause the firing atmosphere of oxidation or reduction, and affect the color of pottery. Therefore, the pottery kiln is the main symbol to measure the level of pottery making technology.

According to the relevant data of ethnology, the most primitive and backward firing technology is flat firing pottery, or flat firing. There is no fixed kiln site in this way of production. We choose an open space to make pottery billet.

Stack it up, cover it tightly and paste it tightly with mud, add firewood in one fire, and open a few small openings as flue. Because of uneven firepower, low temperature, poor sealing, uneven color and brittle texture of pottery after firing. No pottery kiln was found in the first stage of Dadiwan. Red and black patches were often found on pottery. The color was not very pure and the pottery pieces were fragile, indicating that the firing technology was relatively primitive and backward.

Thirty-five pottery kilns have been found in Yangshao culture of Dadiwan, which is the largest archaeological excavation in Gansu Province. In addition, six well-preserved pottery kilns were found at the Zhaocun site of Tianshuishi. Among these pottery kilns, only two shallow hole flat bottom kilns are similar to those of flat ground pottery firing, while the others are more advanced horizontal hole kilns. The pottery kiln of the second stage of Dadiwan No. Y200 is a shallow cave flat-bottom type, which is oval in shape. It is a shallow pit with a depth of 0.16 meters. On the left side, there is a small earth wall separating the kiln chamber from the fire pond. There are 0.3 meters gap between the two ends of the earth wall as a fire passage, and below the left side of the kiln is an operation pit for adding firewood and fire (Figure 1). This kiln fire pond and kiln room on a horizontal platform, the fire is not as vigorous as the Hengcave kiln, but deep below the ground, the fire can borrow the wind power of the operation pit, and progress than the flat pottery, the fire will be stronger, and the partition wall can make the pottery heating more uniform. The pottery kiln No. Y800 of Dadiwan Phase IV is a typical horizontal cave kiln, with a rectangular deep pit on the left and a circular kiln on the right, with three fire channels in the middle (Fig. 2). In some kilns, the flue is dendritic, and the ceramic billet is heated more evenly. This kind of kiln site fire pond is below, the kiln chamber is above the slope, the firepower is vigorous, can reach the high temperature of about 1000 degrees Celsius.

On the North Bank of the Yellow River, 11 kilometers east of Lanzhou City, there is a famous Majiayao cultural Ma Chang type site, where a large-scale kiln was found. Archaeologists cleaned up 12 pottery kilns. According to the site damaged, excavators judged that the original kiln sites were more than 12, which showed the prosperity of the pottery industry at that time. According to the briefing, the upper kiln is square with the largest length.

The width is 1 meter each; the bottom of the pot is the bottom of the pot, with a deposited layer of lime soil, which should be the grass ash formed by burning firewood. Judging from the phenomena of relics, the upper part of this kind of kiln is the kiln chamber and the lower part is the fire pond, which may be a more advanced vertical cave kiln than the horizontal cave kiln.

The structure of the pottery kiln is different, and the temperature inside the kiln - and the degree of sealing are also different. Therefore, the pottery kiln determines the firing temperature of the pottery. The more reasonable the structure, the higher the temperature. According to Dr. Ma Qinglin's determination, the firing temperature of the first stage of Dadiwan is the lowest, which is only 750 degrees (+20 degrees). This data is basically consistent with the solid degree of pottery from different cultures. Generally speaking, except for Dadiwan Phase I, most of the firing temperatures are between 900 and 1000 degrees. In addition, from the Majiayao culture to the Qijia and Xindian cultures, ceramic clay or kaolin were used to bake pottery, but the original pottery was never fired. The reason was that the pottery kiln limited the rise of temperature. Porcelain clay needs to be heated to more than 1100 degrees to reach the vitrification temperature.

In pottery firing process, there is also the ability to control firing atmosphere. The firing atmosphere refers to the composition of gases in the kiln and the ability of oxidation or reduction. When the seal of the pottery kiln is not strict, the oxygen in the air oxidizes the substances contained in the body, and the pottery is red or orange after firing. The pottery kiln has better seal and carbon monoxide in the gas, which has the ability to reduce the iron content to ferrous oxide. The pottery after firing is grey or dark grey. With the improvement of pottery chamber, more and more gray pottery is produced in reducing atmosphere, and the hardness of pottery is also improved.

Prehistoric painted pottery is produced under specific historical conditions. Therefore, it has a set of characteristics that are completely different from modern pottery making technology. Recognition of these features is the key to authenticity identification of painted pottery. Some forgers use fast wheels to make pottery, inevitably leaving traces totally different from the clay strip method; some imitations adopt modern industrial pigments, which are obviously different from the natural mineral pigments used in prehistoric pottery; some use electric stoves to burn at high temperature, because of the high temperature, the knocking sound of the body. The sound will be more clear and crisp, and there is also a clear difference from the prehistoric painted pottery fired with firewood in the earth kiln. Therefore, as long as we master the characteristics left over by different pottery making techniques, we will be able to distinguish true and false colored pottery with ease.

-

Chinese Elk Garden Scenic Spot

Jiangsu Dafeng Elk National Nature Reserve is located in the Yellow Sea coast, with a total area of 78,000 hectares, including 2668 hectares in the core area.

Views: 148 Time 2018-12-06 -

Kashgar Ancient City

The ancient city of Kashgar, a national AAAAA tourist attraction, covers an area of 20 square kilometers. The capital of Shule was renamed Panzhi City, the predecessor of Shule City in the Western Han.

Views: 118 Time 2018-12-12 -

Dongjiang Lake Tourist Area Coconut City

Dongjiang Lake Scenic Tourist Area is located in Zixing City, Hunan Province. It is a national scenic spot, a national 5A scenic spot and a national wetland park..

Views: 187 Time 2018-12-12 -

Nanwan Lake Scenic Area

Nanwan Lake, also known as Nanhu Lake, is located in Xinyang City, Henan Province. It is known as the "Pearl of South Henan" and is a famous natural scenic spot of Nanwan Lake. All around th.

Views: 183 Time 2019-02-07 -

Songxian Tianchishan National Forest Park

The Tianchishan National Forest Park in Songxian County, Luoyang City, is located in Xionger Mountains, northwest of Songxian County, Luoyang City, with a total area of 1716 hectares and a forest cove.

Views: 133 Time 2019-02-13 -

Firing Techniques of Dangyangyu Twisted Tissue Porcelain

Dangyangyu Twisted Tissue Porcelain, a special product of Dangyangyu Village, Xiuwu County, Henan Province, is a product of China's National Geographic Indicators..

Views: 170 Time 2019-04-25 -

Pinghu cymbal book

Cymbals are a unique form of local traditional folk art in the Wu dialect area of Jiangnan. According to the Records of Songjiang County, it was formed in the Qing Dynasty (1821-1850). It is now mainl.

Views: 134 Time 2019-06-09 -

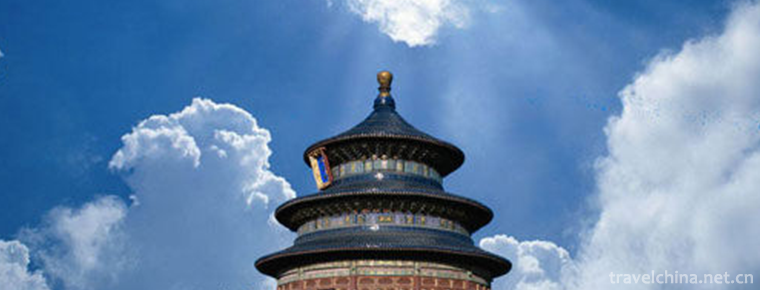

Legend of the Temple of Heaven

On May 18, 2010, the Ministry of Culture of China announced the third batch of national intangible cultural heritage list of recommended projects (new entries). The first item in the category of folk .

Views: 137 Time 2019-06-21 -

Wulin Diao

Wulin Diao evolved from the folk propaganda of Baojuan and formed in the late Qing Dynasty. The performance form of Wulin tune is mainly sitting and singing, which combines narrative and singing. One .

Views: 386 Time 2019-06-30 -

Ningbo Opera

Yong Opera is a local opera sung in Ningbo dialect of Zhejiang Province. Its musical tone belongs to Tanhuang. After 1938, this opera genre was officially called "Yongju" or "improved Y.

Views: 182 Time 2019-07-14 -

Really Different zhenbutong Making Skills of Luoyang Watermat

It's really different from Luoyang's water mat making skills. The traditional handicraft in Luoyang City, Henan Province, is one of the national intangible cultural heritages..

Views: 125 Time 2019-07-25 -

Ding Zhens voice is on the rise and the tiktok of Ganzi Sichuan has doubled

In November 11th CCTV news and Oriental tiktok were put on a short video of the tremble. Ding Zhen, the "sweet boy" in the video, triggered a phenomenal network event with a transmission volume of more than 5 billion times. At the same time, Ding Zhen also became the propaganda Ambassador of his hometown Litang County, driving the search volume of "Litang" to soar by 620%..

Views: 86 Time 2020-12-07